Estimating the cost of high temperature liquid metal based concentrated solar power

Abstract

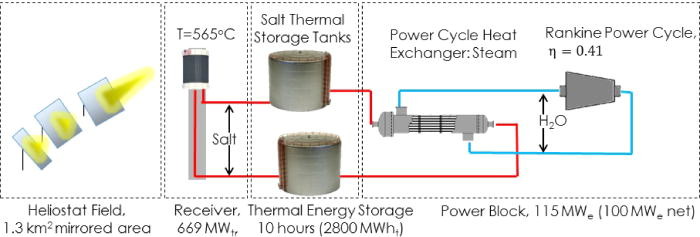

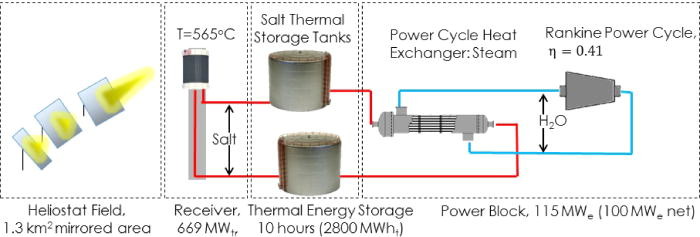

The current levelized cost of electricity from concentrated solar power is too high to directly compete with natural gas under current carbon emissions policies. An approximate 50% cost reduction is needed relative to current power tower technology based on molten nitrate salts, and one pathway to a major cost reduction is to operate the system at higher temperatures, enabling a more efficient heat engine. Here, we consider a future system that can operate at gas turbine inlet temperatures of ∼1300–1500 °C by using liquid metals as heat transfer and storage fluids with a ceramic based piping infrastructure. In general, ceramics are more expensive than the current stainless steels, but they are less expensive than the nickel alloys that are proposed to be used in higher temperature chloride molten salt plants. Considering various tradeoffs, it was not clear a priori whether or not the potential gains in heat engine efficiency would be negated by increased material costs or how much net reduction in levelized cost might be possible. This study answers this question by first detailing a base case molten nitrate salt power tower plant with published cost data. Then, a future liquid metal version of a power tower is modeled using similar specifications as the liquid salt plant to determine if there are any obvious costs that might negate the efficiency gains associated with operating well above 1000 °C. The results of the analysis showed that although the receiver and several other sub-systems become more expensive, there is a net cost reduction in the range of 20%–30%, depending upon the heat engine efficiency.