Thermal Energy Grid Storage (TEGS) Prototype

Overview

TEGS Prototype

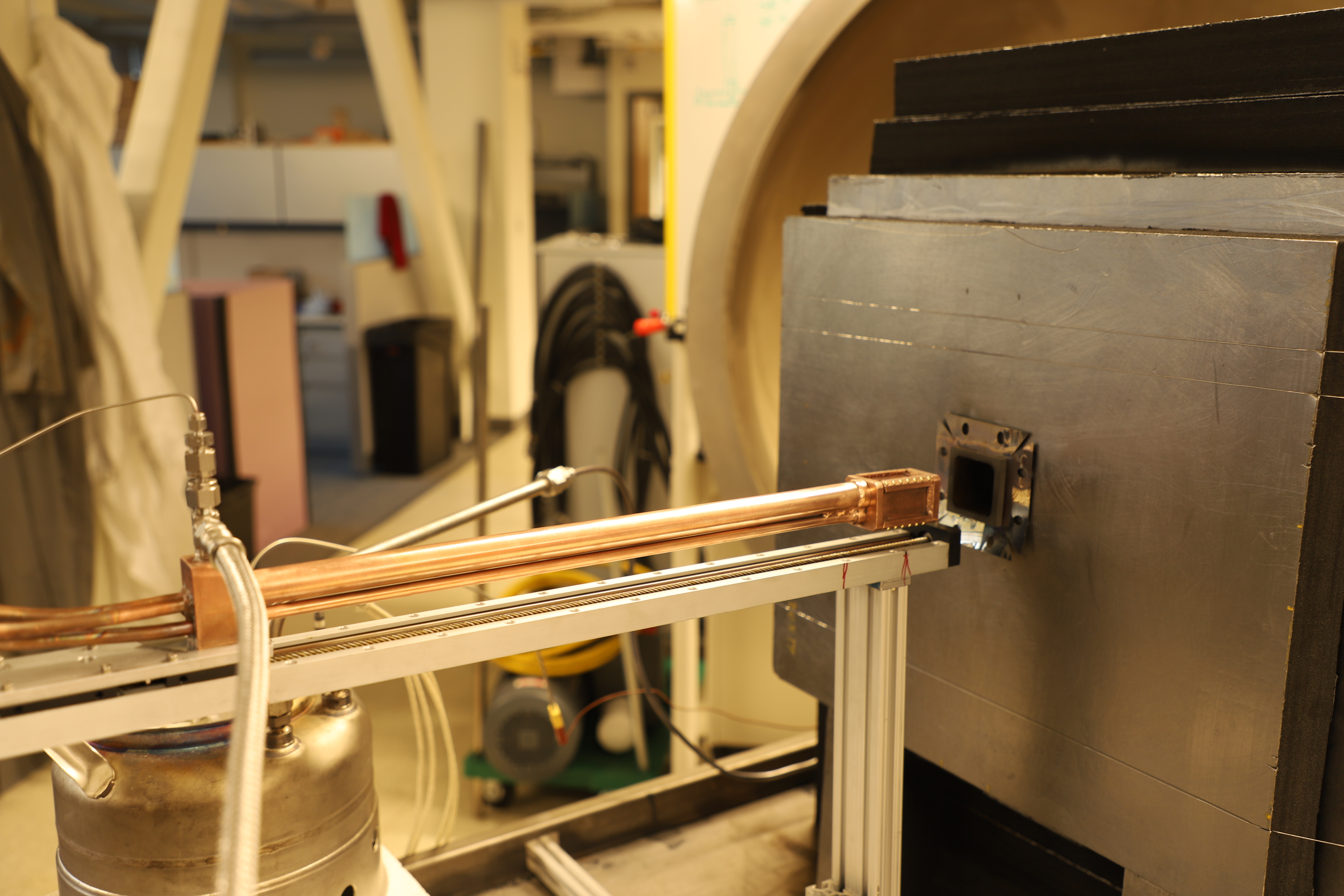

Our thermal energy grid storage (TEGS) system combines a unique type of power conversion device called a multi-junction thermophotovoltaic (TPV) heat engine with a pumped liquid metal loop. We are currently building and testing a prototype system in the lab. The system shown here was built to test the heat to electricity conversion components of the technology. It is composed of a graphite cavity heated by a graphite heater and surrounded with graphite insulation. A heat sink can be actuated into the cavity for TPV testing.

Heater

Although joule heating is simple in concept, designing a system with heaters that operate at ~2000°C is non- trivial. For example, electrically isolating the heater at this temperature is a challenge because even the best insulators (e.g., MgO, ZrO2) begin conducting electricity as they reach this extreme temperature. Another challenge is preventing melting/evaporation of the heater, which requires careful design of the geometry to avoid small areas where it can overheat. A third challenge is arcing which occurs when electricity travels through the gas and produces a plasma which is destructive to components. The use of a gas like argon can help to suppress arcing, as well as designing the heater to operate at low voltages.

TPV Cells

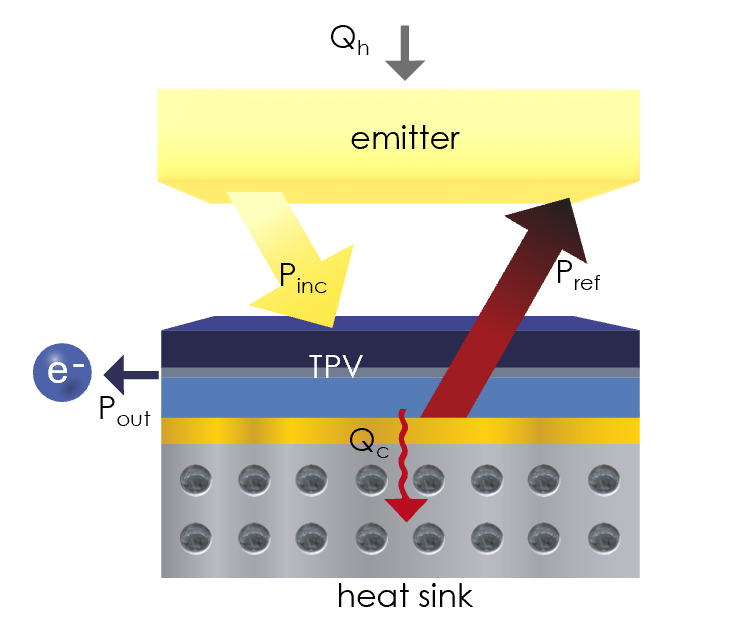

The TPV cells are specially engineered to efficiently convert the spectrum of light emitted by the heater to electricity. They consist of two different photovoltaic cell types and a back surface reflector (BSR). Each cell type is tuned to convert a portion of the spectrum. Recently, we demonstrated record TPV efficiencies of 41%.

A certain portion of the emitted spectrum is unable to be converted to electricity due to its low energy (i.e. sub-bandgap energy photons). The BSR reflects this infrared light back to the emitting surface where it is reabsorbed as heat, effectively recycling it and reducing the energy input required to keep the emitter hot at steady state. The BSR is an important aspect of achieving high TPV conversion efficiency.

Cell Cooling and Durability

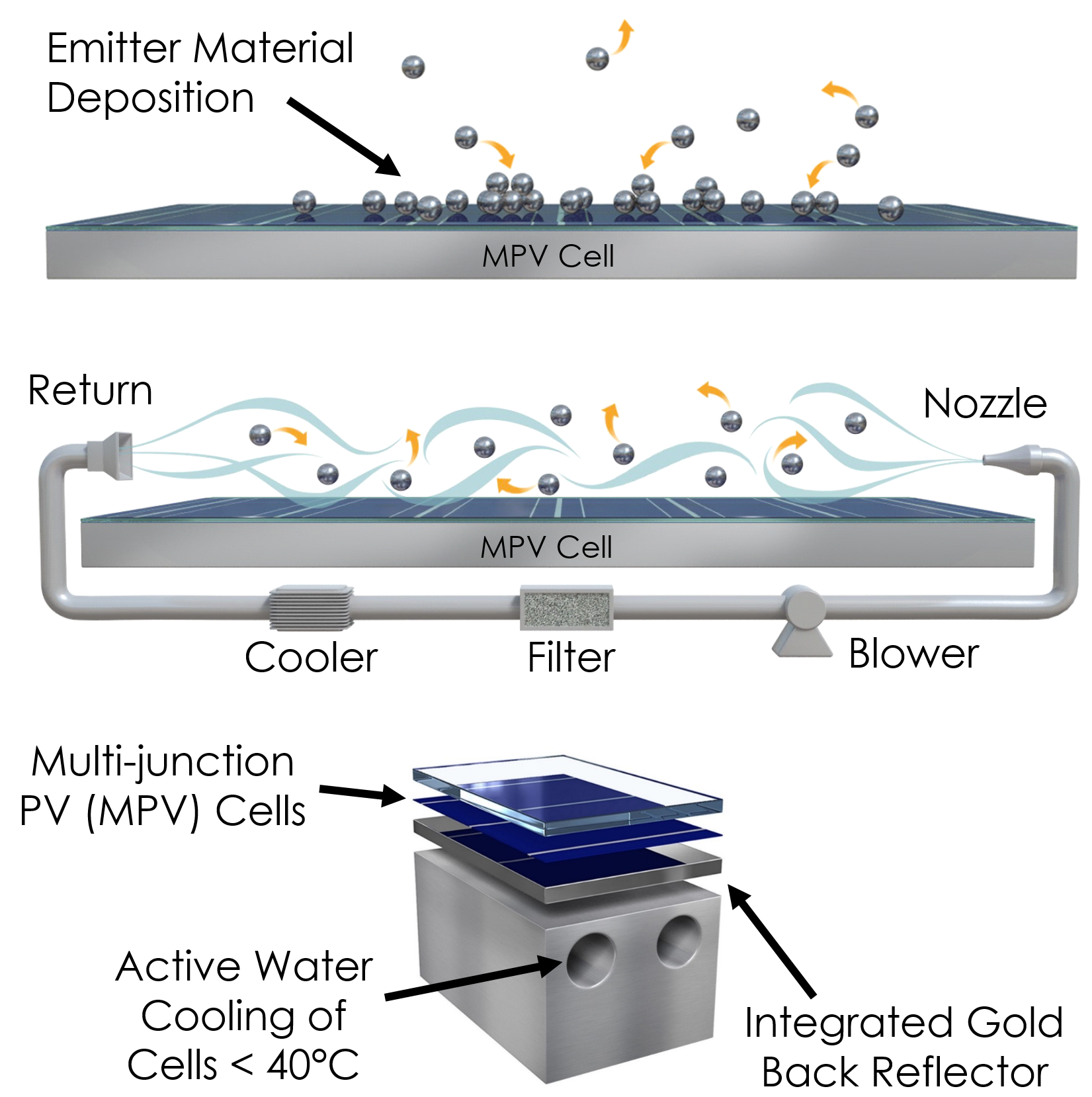

Heating the emitter component to such high temperatures enables high conversion efficiencies, but also increases the evaporation rate of the emitter material. Deposition of this evaporated material on the cell surface can cause performance degradation by blocking the incoming light. To prevent this contamination process, a layer of gas can be blown across the cell, effectively sweeping the evaporated material away before it gets to the surface.

In addition to material contamination, elevated cell temperatures can also negatively affect performance. The light from the emitter is >1000 times stronger than sunlight and liquid cooling is required to keep the cells from overheating.

Insulation

With a thermal storage system like TEGS, insulation is critical to enable high efficiencies. Any heat that escapes from the storage block, heat transfer fluid pipes, or heat engine cannot be converted to electricity and is wasted.

Unfortunately, most traditional glass and ceramic based insulating materials can’t operate at the high operating temperature of TEGS (>2000°C). Therefore, the prototype system uses porous graphite insulation in the hottest areas.