ARPA-E Team Demonstrates Liquid Metal Pumping at 1350C

April 6, 2016 | Asegun Henry

The Floor is Lava

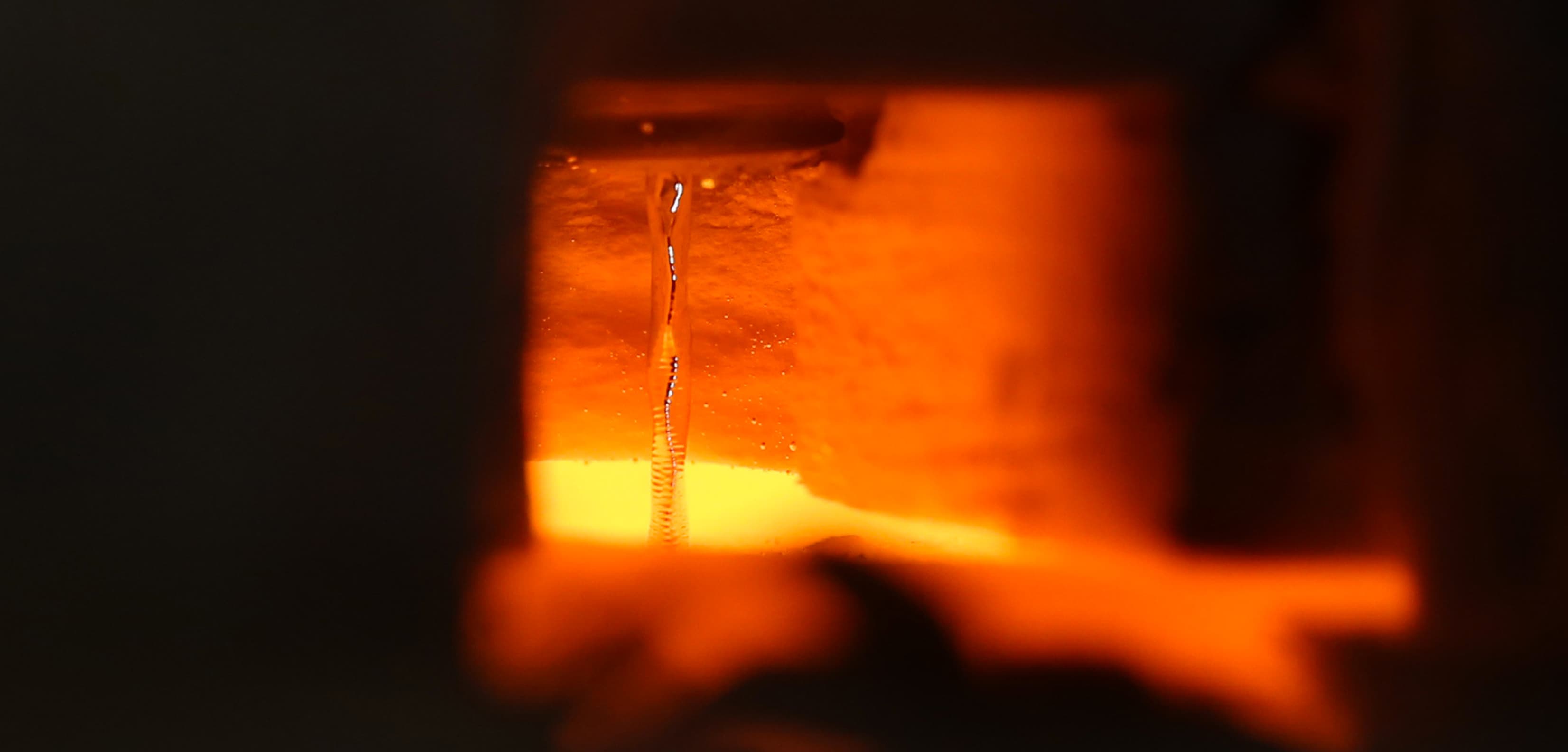

Last week the ARPA-E team succeeded in reaching one of the most important milestones of the project, namely pumping liquid tin (Sn) at 1350C with an all ceramic pump. This milestone is a huge success for the project and to our knowledge sets the record for the highest temperature fluid ever pumped continuously (i.e., where the pump components operate at the peak temperature. This successful proof of concept opens the door to many new potential applications and most notably high temperature concentrated solar power (CSP). (see video below)

Thermal energy, fundamental to power generation and many industrial processes, is most valuable at high temperatures because entropy – which makes thermal energy unavailable for conversion – declines at higher temperatures. Liquid metals such as molten tin and molten silicon could be useful in thermal storage and transfer, but until now, engineers didn’t have pumps and pipes that could withstand such extreme temperatures.

“The hotter you can operate, the more you can convert thermal energy to mechanical energy or electrical energy,” Henry explained. “But when containment materials like metals get hot, they become soft and that limits the whole infrastructure.”

Ceramic materials can withstand the heat, but they are brittle – and many researchers felt they couldn’t be used in mechanical applications like pumps. But Henry and graduate student Caleb Amy – the paper’s first author – decided to challenge that assumption by trying to make a ceramic pump. “We weren’t certain that it wouldn’t work, and for the first four times, it didn’t,” Henry said.

The researchers used an external gear pump, which uses rotating gear teeth to suck in the liquid tin and push it out of an outlet. That technology differs from centrifugal and other pump technologies, but Henry chose it for its simplicity and ability to operate at relatively low speeds. The gears were custom-manufactured by a commercial supplier and modified in Henry’s lab in the Carbon Neutral Energy Solutions (CNES) building at Georgia Tech.